![]()

On the east side of the city of Peoria in the state of Illinois you will find a very special factory. We got an invite to access all areas of the Caterpillar tractor assembly plant and watch them build their big machines. Darren Scully takes you inside the Big Cat sanctuary.

When we arrive at the building, we are met by Caterpillar dealer customer representative, Ryan Sides. Very quickly it becomes apparent that Ryan loves his job and who he works for. His knowledge and passion for bulldozers is infectious, this is going to be a good day. Now, in the states they don’t call bulldozers, you know, bulldozers. They call them tractors and that I believe goes back to the start of Caterpillar when the original founder was the Holt manufacturing company.

The boss, Benjamin Holt, noticed that a lot of steam tractors in the early part of the 1900s were very heavy and would sink in soft soil and therefore became useless when it came to ploughing a field. Mr. Holt decided it would be a very clever idea to wrap around the two axles a chain with planks attached and therefore spread the weight. This worked a charm and now the tractor could plough a soft field. A photographer who captured the moment remarked to the clever Benjamin that his tractor moved like a caterpillar. Bingo!! Very soon after that a new company name was born and the rest as they say is history.

What they build

Here in this factory they build models from the D6T right up to the big beast which is the D11T. They also build the pipe laying models which are the PL72, PL83 and the PL87. The highest volume of dozer manufactured in the factory is the D6T. This is because this type of dozer and its size is very popular with the general civils contractor and in the gas and oil industry. On average it can take 9 days to build the larger dozers from scratch.

The smaller ones from D6 up to D8 can take on average 7 days. They are currently rolling 13 dozers a day off the assembly line but that can depend on demand. They can significantly up that number if there is a surge in construction or mining projects. The maximum number they can complete is 27 dozers a day and were doing that back in 2012. The global chain of Cat dealers and the US military order their dozers direct from the factory.

The biggest customer for Cat dozers is unsurprisingly the United States department of defence. The trusty bulldozer has always played a vital part when building roads and infrastructure on the battlefield. And, if you want your machine painted in colour, no problem, they can do that at the factory.

The tour

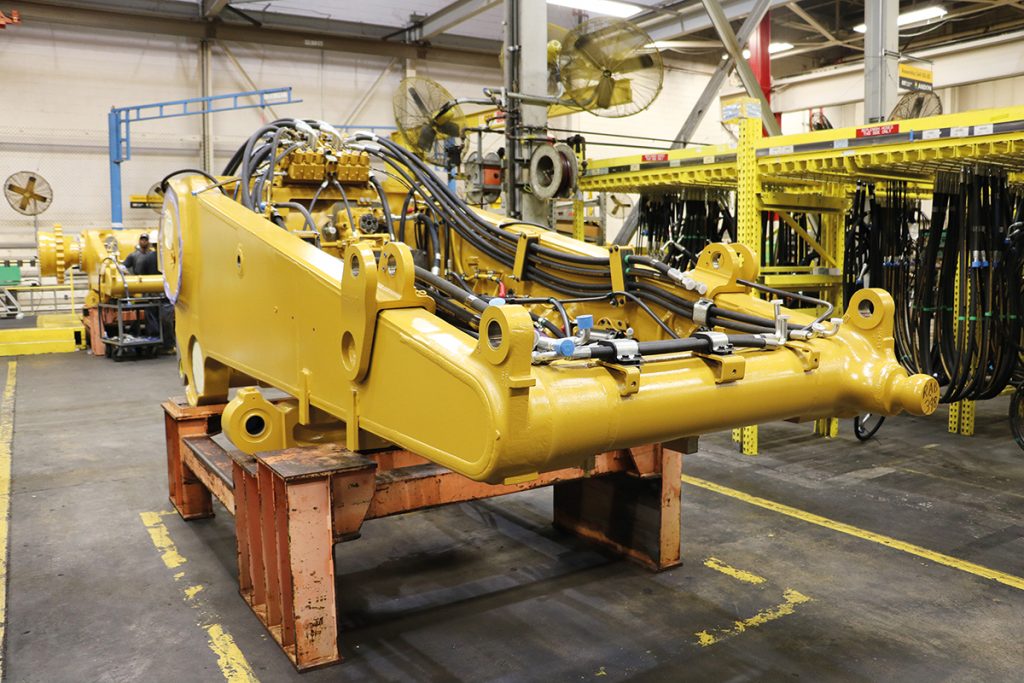

With hard hat and safety glasses on we are taken into the heart of the factory. We start with where they are putting the chassis/frame together. Then it is painted that famous Cat yellow and it is put onto a stand. The front bogey is then attached and is all the necessary pipe work. Now it is time to fit the final drives and the transmissions. In this room is just a sea of sprockets and gearboxes and a very busy team of technicians beavering away.

When it comes to final drives Caterpillar are renowned for their clever elevated drive sprocket. This design very much makes their bigger dozers instantly recognisable out in the field. The elevated sprocket was a huge impact on the industry and was first fitted to the new D10 in 1977. Caterpillar elevated the final drive and the reasons for this were simple. You were taking this vital component away from abrasive material such as rock and sand and you were also reducing shock loads. This design also helped with creating better comfort for the operator as the track rollers were mounted on bogeys and thus created better traction. This elevated drive sprocket undercarriage was built in modular form and this enabled an easier breakdown of the tracks and removal of the drive sprockets. The transmission can be removed from the rear because of this modular design.

Final stages

We now move out into the area where they construct the operator cab modules. The dash, seats and controls are all bolted together and then fitted onto the frame. They also assemble the radiators and cab/rops systems and slowly the dozer starts to take shape. On the side of each frame is a small flag which indicates which country that dozer will be shipped. I see the flags of China, South Africa, Australia to name a few. In the next area of the factory we can see all the engines lined up waiting to be fitted. The engines are built in another Cat factory in Indiana and then shipped here for instalment.

The dozers are now on a slow-moving assembly line where tracks, rad covers, hydraulic rams and valve blocks are fitted. All the parts have already been painted so now it is just a question of fitting the decals and of course that famous logo. The machines are now at the finishing line and are hooked up to coolants and an exhaust extractor to be fired up. The dozers are put through extensive tests and quality control check and then double check every nut, bolt and washer.

The dozer is now ready to be shipped to its happy new owner. The machine is now tracked outside to a massive parking area waiting to be loaded onto low-loaders or indeed rail cars. Caterpillar have a long and proud tradition of building top quality construction equipment.

To see the men and women of Illinois using their skills to create these fantastic machines was a joy to watch. So next time you see a Cat dozer hard at work and wonder where they build them and how, now you know.

Big Cat up close

When you have a Caterpillar D11T sitting there in front of you, what do you do? Well you get yourself all over it, examining every nut and cranny, you fire her up and just marvel at the engineering magnificence. That’s what I did for a glorious hour.

Under the hood you will find a Cat C32 engine with ACERT technology. This is a V12, twin turbo charged diesel engine that pumps out over 900 horses. Engine enclosures provide easy access to maintenance points within the engine compartment. Easier maintenance and repair is available through monitoring of key functions and logging of critical indicators. The hydraulic variable demand fan provides engine cooling capability that is matched to the ambient conditions. In cooler conditions, the fan turns at a slower speed consuming only the power required to cool the tractor systems, providing more power to the tracks to help you lower your cost per unit of material moved.

This dozer uses a torque divider between the engine and the transmission to act as the hydrodynamic component, reducing the possibility of damage to the power train by dampening impact loads and vibrations. She has three speeds forward and three speeds reverse, utilizing large diameter, high-capacity, oil-cooled clutches.

The elevated sprocket and suspended undercarriage work together, increasing traction and giving the operator a smoother ride. These benefits translate into higher production and longer component life. This design transfers implement shock loads to the mainframe, so final drives, axles, and steering components are isolated from harsh impact loads commonly seen in large track-type tractor applications.

In the cab the fingertip controls require less effort and are more comfortable for long periods of operation. Low effort and comfortable to grip, the electronic dozer joystick gives the operator control of all dozer functions with the right hand. The operator station offers an exceptional viewing area. The tapered hood, notched fuel tank, and narrow ripper carriage give the operator a clear line of sight to front and rear work areas. The combination dash mounted instrument cluster and the right console mounted Advisor Monitoring System display key machine operating information and give operators and service technicians insight into the machine’s operation and maintenance needs.

This dozer is oozing with electronic gizmos that will making the working day a lot easier. Examples are automated blade assist and slope and side slope monitor are standard allowing operator to understand terrain better to improve dozing performance.

I didn’t get an opportunity to work this dozer out in the field, but I reckon I could have easily moved half the state of Illinois into the neighbouring Indiana. A beautiful machine.